We offer solutions for automatic production and quality control of eco-oil filters for vehicles.

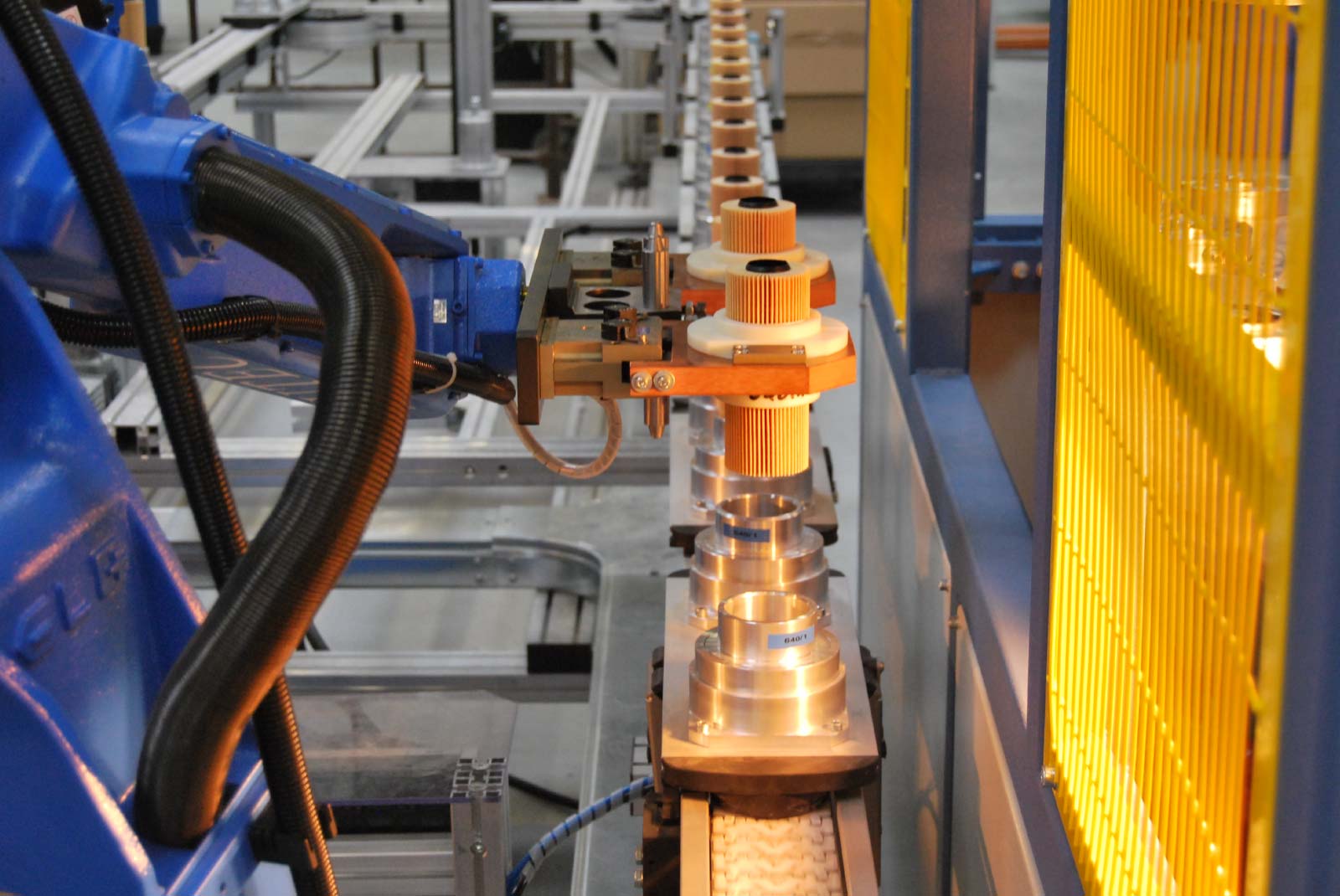

We integrate with the rotary table of our partner GUSBI to automate and have the production process under control from the loading of the paper to the unloading of finished products.

All the process steps

Media loading

The load of the media on the rotary table is automatically performed through the use of an anthropomorphic robot: the concentricity of the coupling of the paper with the endcap is ensured.

Endcaps loading

The load of the endcaps on the rotary table can be done automatically.

We offer different solutions for loading the rotary table, with increasing automation and production autonomy.

Finished products dimensional inspection

The dimensional check is carried out automatically at the end of the production process: a dimensional non-conformity is detected and the not compliance product is expelled from the unloading conveyor.

The integration with the Gusbi rotary table software also allows to expel finished products diagnosed as not compliance from the rotary table software.

Autec in numbers

2 robot on 2 rotary tables

1000-1200 filters/ora

Case Histories

The implementation of applications in different sectors constantly stimulates and allows us to apply proven solutions to new problems to be solved.