We have realized all the automation necessary in the safety shoes field, where a high quality and repeatability of the product over time is required: the roughing robot of the upper and the relase agent robots are of fundamental importance. We have designed and industrialized different production layout solutions with pallet conveyors, in order to make all the shoe assembly phases in a sequential order.

All the process steps

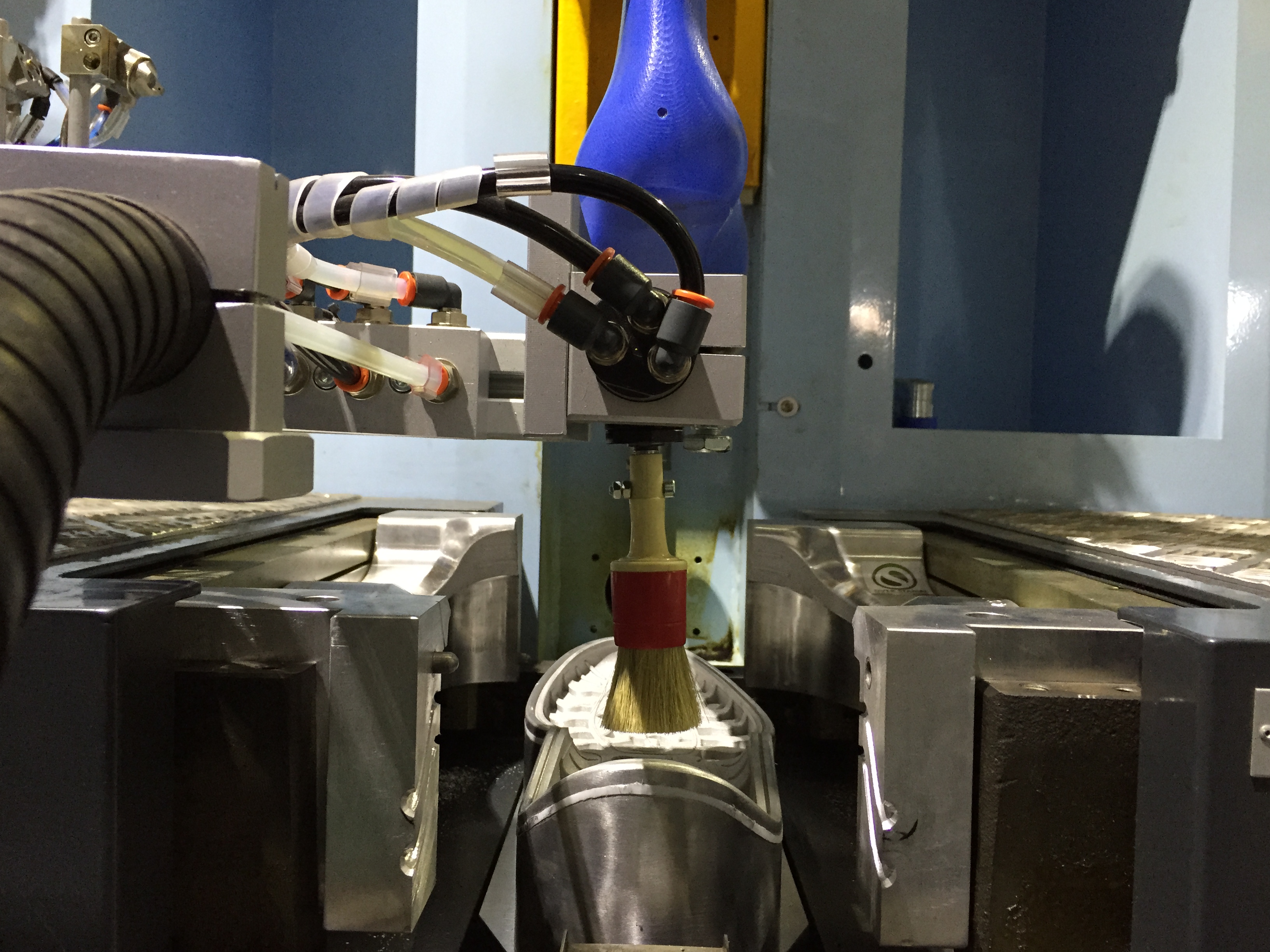

Release agent application

The application of the release agent in the molds is carried out using a robot equipped with spray guns and a rotating brush. The distribution is uniform, allowing a drastic reduction in consumption and an increase in quality.

Roughing

The purpose of the roughing robot is to rough the uppers mounted on lasts, or to remove a small amount of material on the surface in order to facilitate the next adhesion between the upper and the sole. Precision and repeatability of the robot ensure a drastic reduction in scraps.

Production assembly line

We study and propose to the customer the best layout and the best solution to put the shoe assembly phases along a pallet conveyor line.

Case Histories

The implementation of applications in different sectors constantly stimulates and allows us to apply proven solutions to new problems to be solved.