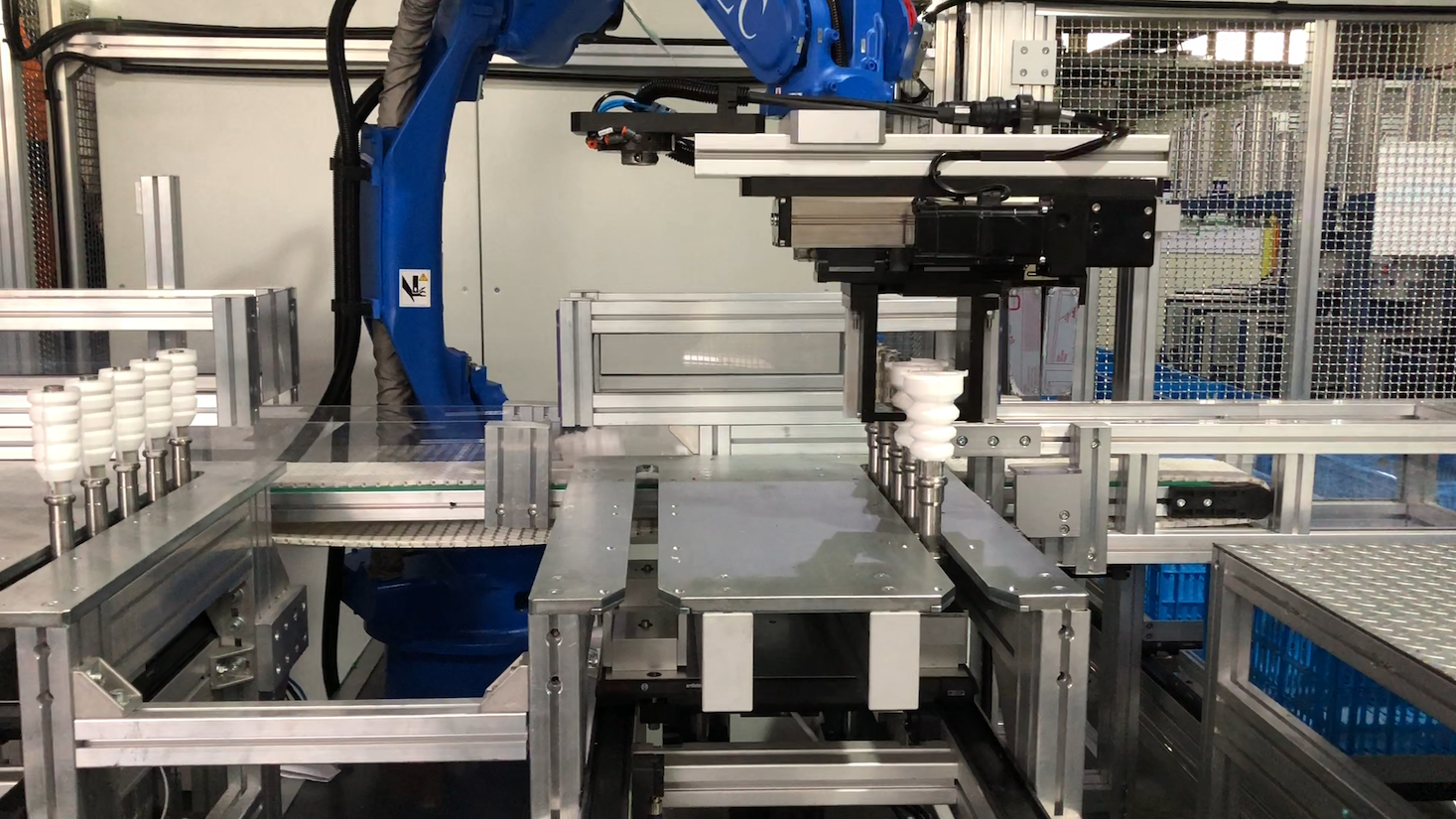

We offer solutions for the automatic production of PU shock absorbers.

We integrate with the rotary table of our partner Gusbi, to automate and have the production process under control, from casting to sorting by model of finished products.

All the process steps

Extraction

The shock absorbers are automatically extracted from the inserts (pins) of the mold by anthropomorphic robot.

Automatic sorting

The shock absorbers are automatically divided into baskets based on the type of item and model.

Application of the release agent on mold inserts (pins), in the mold and on the cover

The release agent application is made using a robot equipped with spray guns and a rotating brush. The distribution is uniform, allowing a drastic reduction in consumption and a quality increase.

Autec in numbers

1000-1200 bumpers/hour

Case Histories

The implementation of applications in different sectors constantly stimulates and allows us to apply proven solutions to new problems to be solved.