The implementation of applications in different sectors constantly stimulates and allows us to apply proven solutions to new problems to be solved.

Automotive

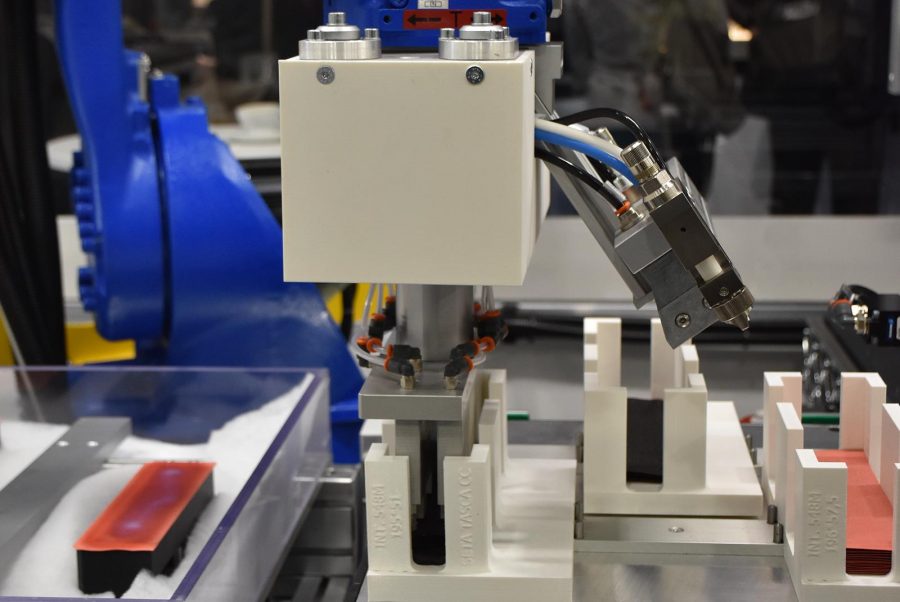

We offer solutions for automatic production and quality control of eco-oil filters for vehicles. We integrate with the rotary table of our partner GUSBI to automate and have the production process under control from the loading of the paper to the unloading of finished products.

Through the 6-axis robot, equipped with spray guns and a tool with a rotating brush, it is possible to reach all the parts of the molds, even the undercuts, which are difficult to be reached with a manipulator. Through the guns all types of release agents on the market (water base, solvent base and wax base) can be sprayed in an adequate quantity and in the right directions; the brush helps this function and allows to distribute the silicon inside the molds while removing the excesses.

We offer solutions for the automatic production of PU shock absorbers. We integrate with the rotary table of our partner Gusbi, to automate and have the production process under control, from casting to sorting by model of finished products.

We offer solutions for the production of air filters for vehicles, integrating with the rotary table of the GUSBI partner. The peculiar characteristic of the production system is flexibility: in each station of the carousel different filter models can be placed and the reprogramming of the robots is rapid and automatic.

Footwear

We have realized all the automation necessary in the safety shoes field, where a high quality and repeatability of the product over time is required: the roughing robot of the upper and the release agent robots are of fundamental importance. We have designed and industrialized different production layout solutions with pallet conveyors, in order to make all the shoe assembly phases in a sequential order.

The automation we make for causal shoes is aimed at ensuring quality and repeatability of the product over time. We offer design solutions to create all the shoe production phases along an assembly line.

In the production of PU boots we automatically make the most of the applications traditionally performed by the operator, giving the possibility to concentrate on the quality control of the finished product.

We offer the possibility of automatically performing all the applications in the field of PU soles production. We allow not only the elimination of operators to perform harmful activities from the point of view of health (painting, siliconing …) but also the quality increase of the finished product.

Leather goods

The applications take advantage of the sectors in which we have the most experience: automotive and footwear. We work with identified, tracked and pieces in referred position and we know how to combine the merits of a production with large batches with those of a production for smaller and different lots, providing functional and value-added automation.

Other sectors

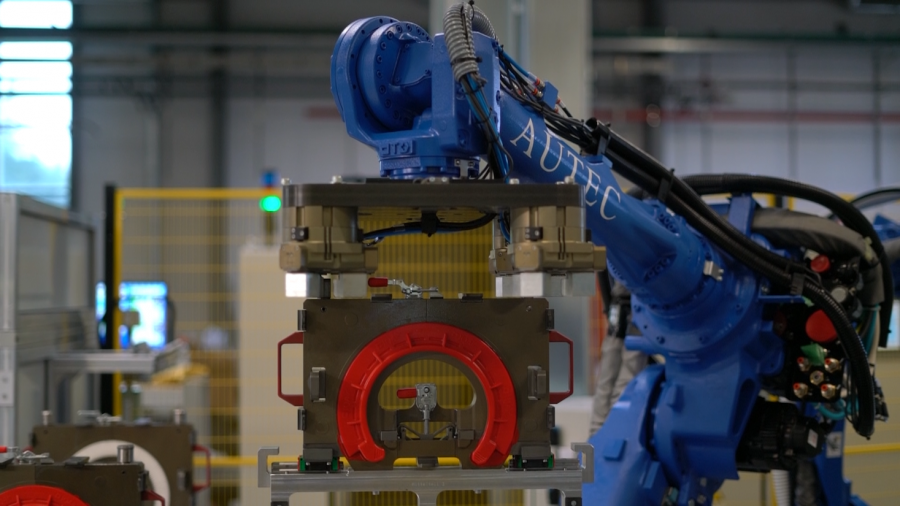

The plant allows the production of air purification filters thanks to the integration between the pallet transport system, on which the mold components travel, and the rotary system on which the polyurethane casting takes place. Preliminary operations for preparing the mold components and the finishing of the molded filter are carried out along the pallet line. A 6-axis robot unloads the mold component containing the casted piece from the carousel and loads the component of the mold containing the insert to be poured. A second 6-axis robot takes care of applying release agent on the molds. A third and a fourth robot move the casting heads.

Through the 6-axis robot, equipped with spray guns and a tool with a rotating brush, it is possible to reach all the parts of the molds, even the undercuts, which are difficult to be reached with a manipulator. Through the guns all types of release agents on the market (water base, solvent base and wax base) can be sprayed in an adequate quantity and in the right directions; the brush helps this function and allows to distribute the silicon inside the molds while removing the excesses.

Through the 6-axis robot, equipped with spray guns and a tool with a rotating brush, it is possible to reach all the parts of the molds, even the undercuts, which are difficult to be reached with a manipulator. Through the guns all types of release agents on the market (water base, solvent base and wax base) can be sprayed in an adequate quantity and in the right directions; the brush helps this function and allows to distribute the silicon inside the molds while removing the excesses.

We have build systems for the automatic washing of garbage vehicles with a partner company. The vehicle enters in the washing area and stops in a fixed area. The system automatically recognizes the type of vehicle and loads all the data necessary for washing. The operator selects the type of washing required via touch-screen and starts the washing cycle. This technology reduces the possibility of error to zero.