We offer solutions for the production of air filters for vehicles, integrating with the rotary table of the GUSBI partner.

The peculiar characteristic of the production system is flexibility: in each station of the carousel different filter models can be placed and the reprogramming of the robots is rapid and automatic.

All the process steps

Release agent application

The application of the release agent in the molds is carried out using a robot equipped with spray guns and a rotating brush. The distribution is uniform, allowing a drastic reduction in consumption and an increase in quality.

Trimming

Using conventional trimming machines, we carry out the automatic trimming of air filters, obtaining a high quality product.

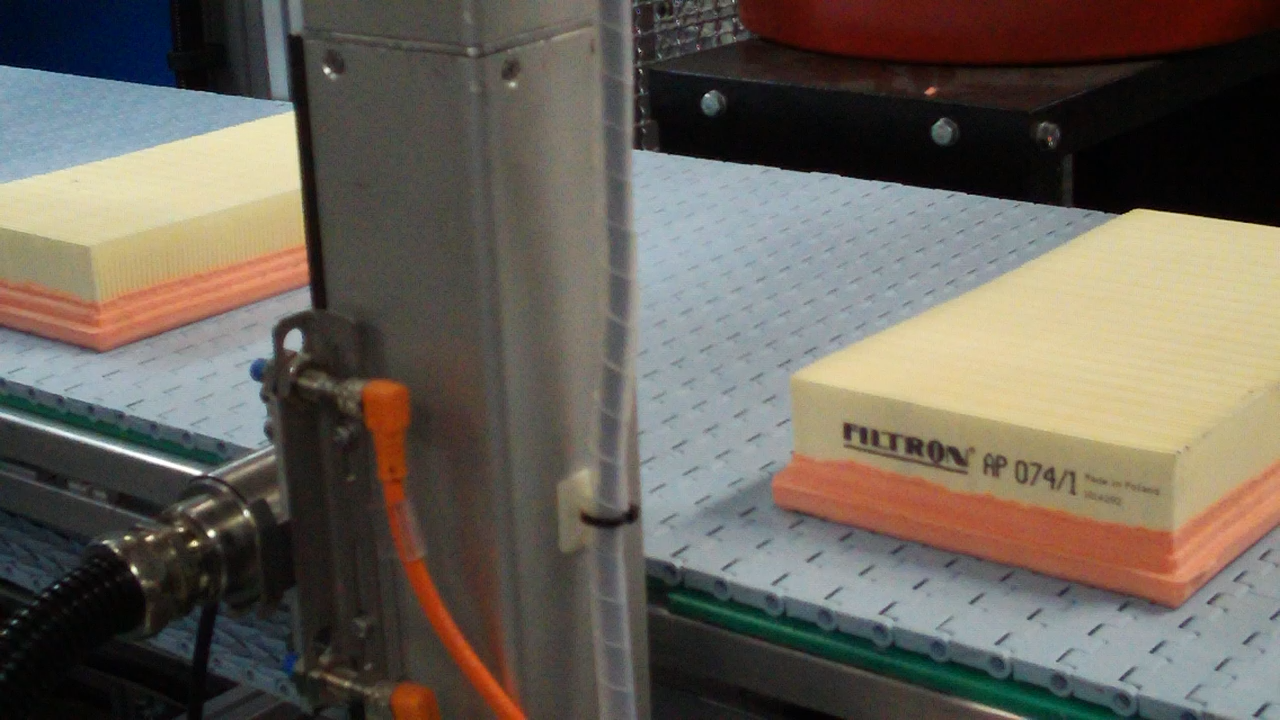

Ink Ject printing

It is possible to integrate inkjet printers for marking individual filters. Placing them along the line it is possible to automatically print, according to the type of filter moving on the pallet, the correct label. The information is easily transmitted to the printers since the type of filter on the pallet is known.

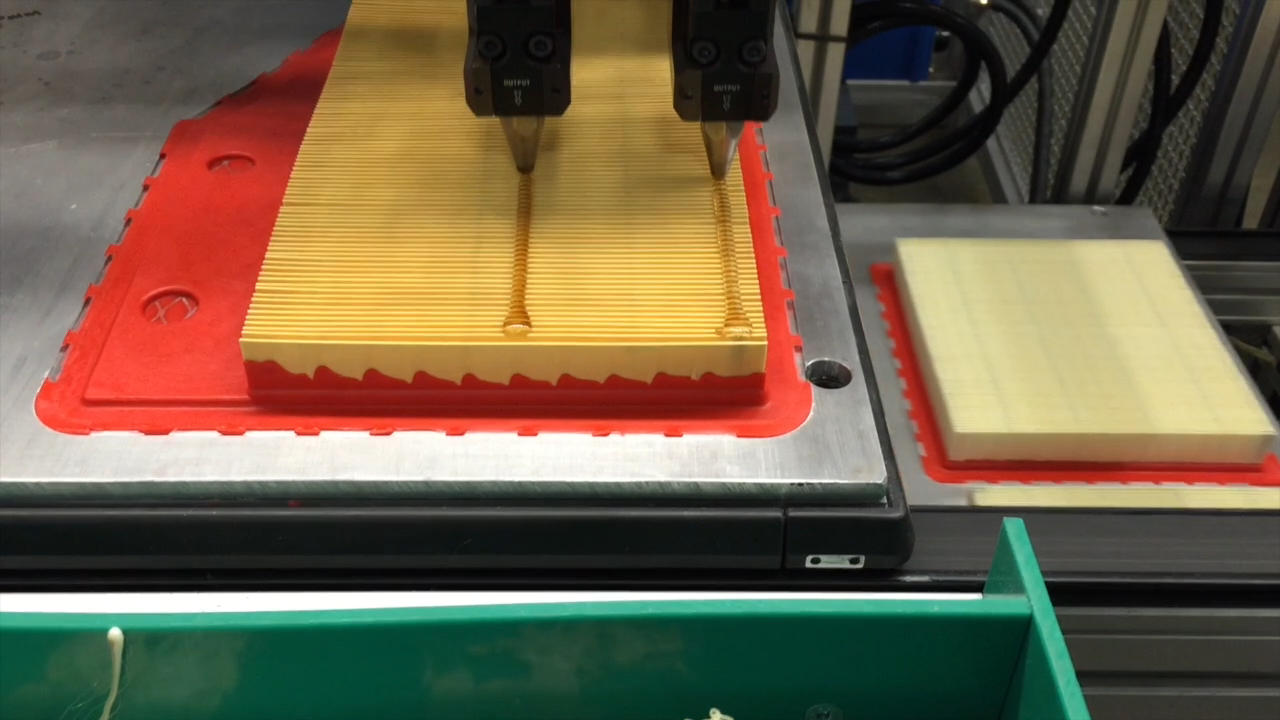

Hot melt application

We carry out the application of the hot melt using a robot equipped with several guns, placed at a variable distance and programmable with numerical control. Depending on the type of filter, the robot applies the hot melt following the appropriate cycle. It is possible to obtain not only rectilinear trajectories and in all possible directions.

Case Histories

The implementation of applications in different sectors constantly stimulates and allows us to apply proven solutions to new problems to be solved.