OTHER SECTORS

Automatic production of air purification filters

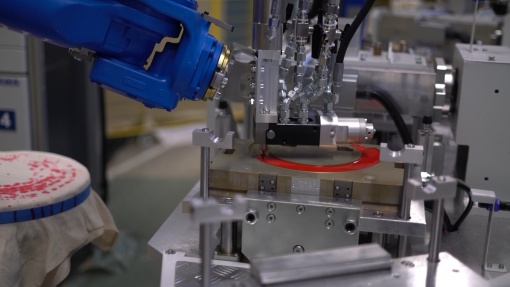

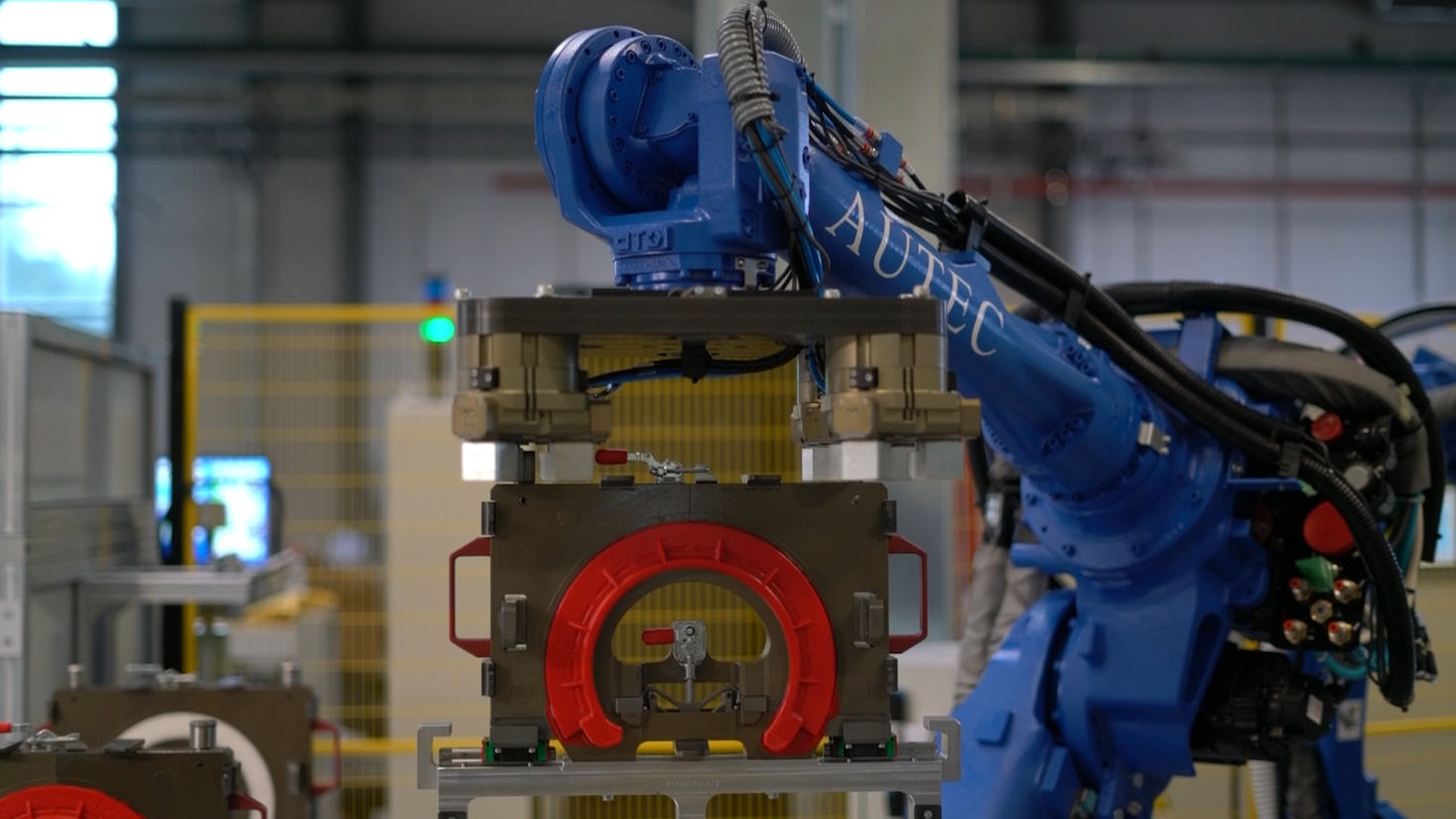

The plant allows the production of air purification filters thanks to the integration between the pallet transport system, on which the mold components travel, and the rotary system on which the polyurethane casting takes place.

Preliminary operations for preparing the mold components and the finishing of the molded filter are carried out along the pallet line.

A 6-axis robot unloads the mold component containing the casted piece from the carousel and loads the component of the mold containing the insert to be poured.

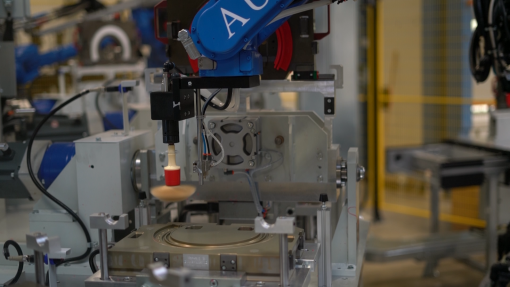

A second 6-axis robot takes care of applying release agent on the molds.

A third and a fourth robot move the casting heads.