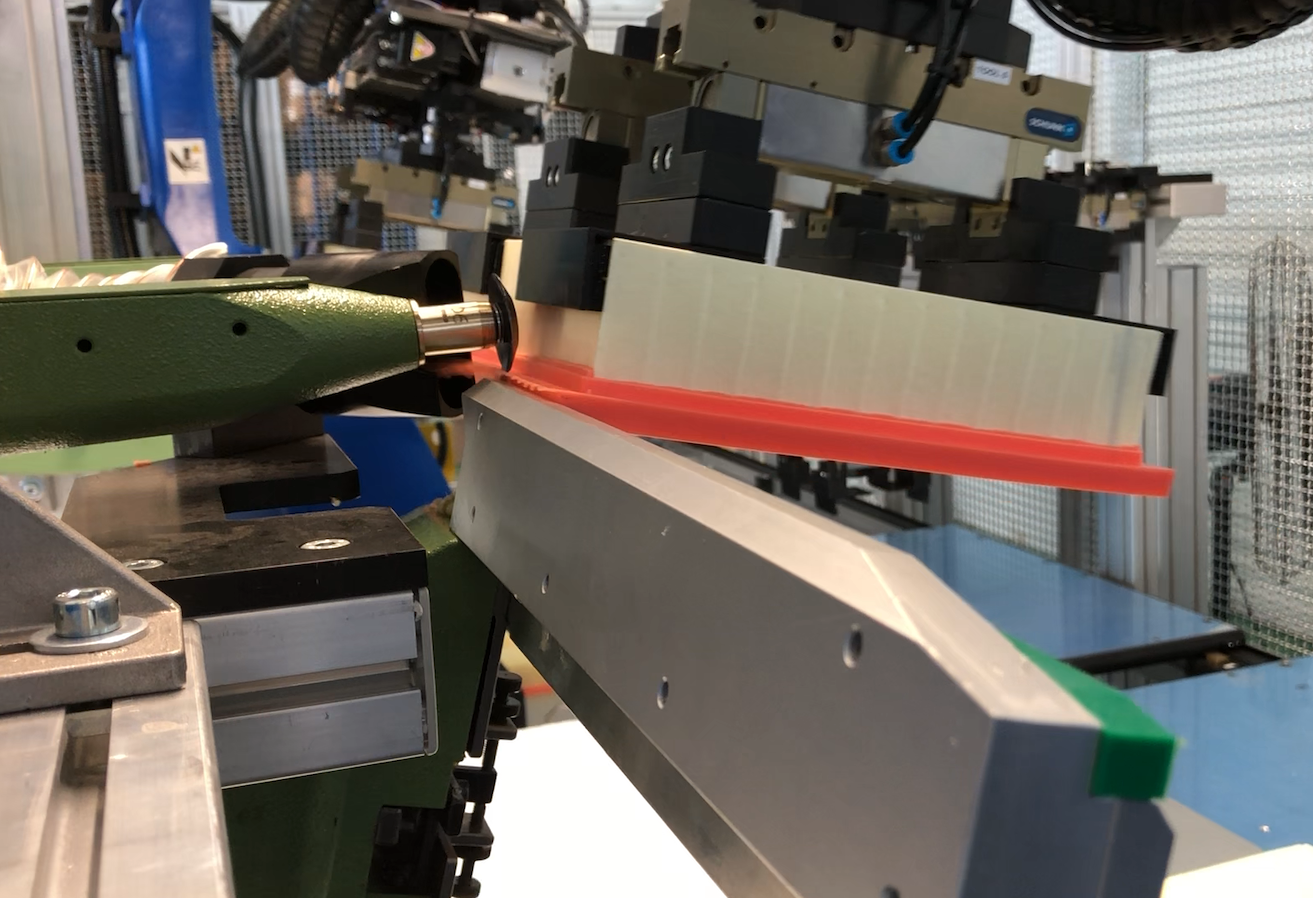

Trimming

An anthropomorphic robot picks up the filter from a pallet of a conveyor line through special grippers and rotates it smoothly, precisely and with constant speed around the trimming blade. This allows to get an high quality product.

In detail

The trimming plant consists of a pallet line on which the filters are placed once they are extracted from the rotary table. The conveyor pallets are in a number equivalent to the number of stations of the rotary table and on each pallet there are positioned all the filters of the corresponding mold of the carousel.

The pallets, being equipped with transponders, are identified as the filter (s) they carry are identified.

This allows the online adjustment of the trimming program as well as the relative tool change: the robot selects the appropriate gripper to use on the base of the filter type.

The programming of a trimming cycle is easy and immediate: it is sufficient to set the size of the filter to be trimmed from the PC to obtain an automatic trimming cycle.

The pallet line and the rotary table are integrated and synchronized:

- Every time the rotary table makes a step, a new pallet advances on the conveyor;

- When the operator informs the GUSBI table that a mold has been changed, the information is shared with the AUTEC system. All the robots are therefore automatically reprogrammed, allowing for rapid and automatic set-up.