Roughing

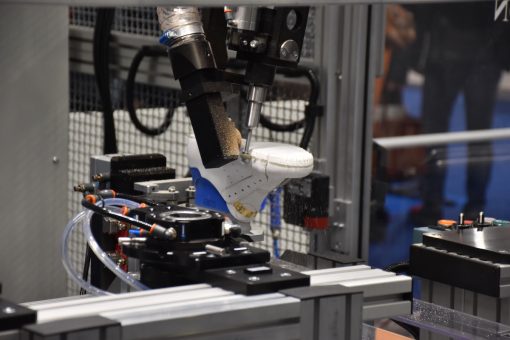

The precision of the robot, equal to 0.06 mm at maximum speed with a weight of 25 kg applied to the wrist, allows for accurate and repeatable roughing profiles.

The distinctive feature is the extreme ease of programming the robot and the efficiency in changing the roughing program.

It is necessary to program the robot only the first time the last enters production. A digitizer like a microscribe can be used, without the need to memorize the points from the teach pendant, but following the roughing path wanted. The software developed by us processes the coordinates transmitted by the microscribe and determines the optimal roughing path.

Once the program has been defined, it is stored in the PC memory and can be recalled by PC, entering the model number and size, or automatically with an RFID identification of the plastic lasts.

Roughing robot on the rotary table

Roughing Island or Roughing on the conveyor line

In detail

The particular configuration of the roughing tool that we developed makes the system extremely flexible as it is able to adapt to various types of lasts and to various thicknesses of the upper leather.

We provide the option of an automatic tool change: depending on the type of upper that the robot has to rough, it automatically chooses the particular preset tool.

If necessary, the robot can also be equipped with a gun for applying glue along the roughed profile.

Autec in numbers

330-400 pairs/hour